Our Products

Comprehensive solution provider for the network infrastructure.

Comprehensive solution provider for the network infrastructure.

Customized Fiber Optic Cable

Premium Line dedicated fiber optic technical team capable to design various telecom systems cables for you base on requirements or provided location climate information where intend to use.

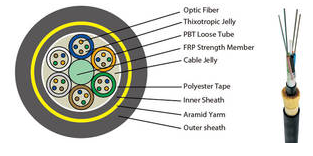

All Dielectric Self Supporting Fiber Optic Cable

This kind of cable more often be installed on overhead power lines, gantries or poles, its’ all dielectric construction protect it against electric shock impact or damage.

Normally, you can provide us the local climate information also the electrical field strength to design it accordingly.

|

Cable Physical / Environmental Performance |

|

|

Maximum Span |

100 meters |

|

Cable Sag (%) |

1.0% |

|

Temperature Range |

-20 °C to +70 °C |

|

Worst Environmental Conditions |

100 kms/hr wind speed (No Ice) |

|

Cable Characteristics |

|

|

Maximum Working Tension (No Fiber Strain) |

4.12 kN (420 kgs) |

|

Estimated Tensile Strength |

10.3 kN (1050 kgs) |

|

Thermal Coefficient of Expansion |

20.83×10 -6 °C |

|

Area of Aramid |

4.5 mm² |

|

Approx. Cable Weight |

120 kgs/km |

|

Cable Diameter |

12.2 mm |

|

Radial Thickness of Sheath |

1.5 mm |

|

Minimum Bending Radius |

Dynamic 700 mm, Static 350 mm |

|

Crush Resistance |

2000 N/10 cm |

|

Water Penetration |

No water penetration of the cable core, on a 3 meter sample, with a 1 meter head of water applied for 24 |

|

Outer Sheath Materia |

HDPE (non anti-tracking) |

|

Max. Electrical Field Strength |

≤ 12 kV/m tested according to IEEE P1222 |

Environmental Condition and Cable Loads, Sags, etc.

|

Condition |

Temp |

Wind km/hr |

Cable Load kgs |

% UTS |

Sag (mtrs) |

Blow Out |

Cable Elong |

|||||||

|

Vert |

Plane |

|||||||||||||

|

EDS |

25 |

- |

150 |

14% |

1 |

1 |

0 |

0.212 |

||||||

|

Low Temp, No Wind |

0 |

- |

184 |

18% |

0.81 |

0.81 |

0 |

0.203 |

||||||

|

High Temp, No Wind |

70 |

- |

113 |

11% |

1.33 |

1.33 |

0 |

0.233 |

||||||

|

Low Temp, Wind |

0 |

100 |

294 |

28% |

0.51 |

2.55 |

78.4 |

0.358 |

||||||

|

EDS Temp, Wind |

25 |

100 |

273 |

26% |

0.55 |

2.74 |

78.4 |

0.386 |

||||||

|

High Temp, Wind |

70 |

100 |

279 |

24% |

0.6 |

3 |

78.4 |

0.426 |

||||||

ADSS Fiber Optic Cable, 9/125um G652D

|

Number of Fibers |

12 |

24 |

48 |

72 |

96 |

144 |

|

Part No. |

260223012 |

260223024 |

260223048 |

260223072 |

260223096 |

260223144 |

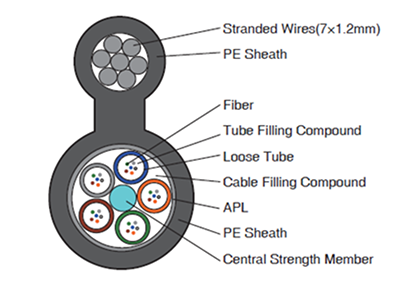

This kind of cable use upper messenger wire to support aerial cabling. It is designed for places with heavy wind weather or even ice frozen climate. The cable requires specified working load tension design to provide capable construction and mechanical characteristics to afford outdoor vile condition.

Normally, it’s recommended to use ITU-G652D fiber for data transmission, other mode upon request, as well as the outer sheath.

Normally, you can provide us the local climate information also the worst wind speed to design it accordingly.

Technical Parameters

|

Parameter |

Units |

Value / Details |

||

|

Fiber Type |

- |

ITU-T G652D |

||

|

Fiber Count |

- |

4, 6, 12, 24 |

48 |

|

|

Cable Diameter |

mm |

9.6 Dia. × 17.0 High. |

10.5 Dia. × 18.5 High. |

|

|

Messenger Wire Dia |

mm |

7 × 1.0 |

7 × 1.2 |

|

|

Cable Weight |

kg/km |

162 |

200 |

|

|

Web Dimensions |

mm |

2.0 Dia. × 2.0 High. |

||

|

Cable Sheath, Radial |

mm |

1.5 Nominal |

||

|

Messenger Sheath, Radial |

mm |

1.2 Nominal |

||

|

Bending |

Dynamic |

- |

≥ 20 × Cable Diameter |

|

|

Static |

- |

≥ 10 × Cable Diameter |

||

|

Maximum Span |

m |

Span ≤ 100m |

||

|

Cable Sag |

% |

Sag ≥ 1.0% |

||

|

Max. Wind Speed |

km/h |

100 (No Ice) |

||

|

Max. Working Load (MAT) |

kN |

3.53 |

4.2 |

|

|

Ultimate Tensile Strength (UTS) |

kN |

8.08 |

11.6 |

|

|

Crush Resistance |

N/10 cm |

1500 |

||

|

Impact Resistance |

Nm |

3Nm with striking surface radius of 10mm |

||

|

Operational Temperature |

°C |

-20°C ~ +70°C |

||

|

Shipping Lengths |

m |

4000 ± 5% |

||

MAT = Maximum allowable tension, or maximum working tension (worse environmental conditions) and ï¬bers have zero ï¬ber strain. UTS = Approx. Breaking strain of the cable

Figure 8 Fiber Optic Cable, 9/125um G652D

|

Number of Fibers |

12 |

24 |

48 |

72 |

96 |

144 |

|

Part No. |

269222012 |

269222024 |

269222048 |

269222072 |

269222096 |

269222144 |

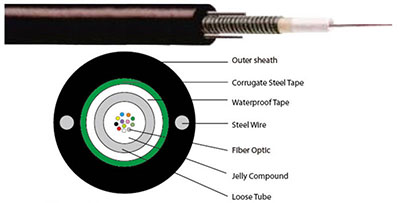

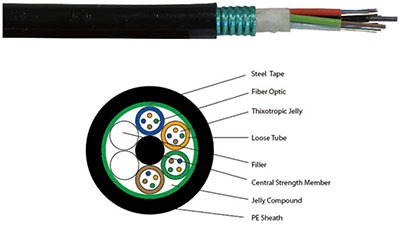

Two parallel steel wires construction cable suits for aerial installation. With additional corrugated steel tape protection make it also available for duct installation.

Structure & Environmental Characteristics

|

Loose Tube |

Material |

PBT |

|

Peripheral Strength Member |

Material |

Steel Wire |

|

Diameter |

1.0 mm |

|

|

Wrapping |

Material |

Waterproof Tape |

|

Messenger Wire Dia |

Material |

Corrugated Steel Tape |

|

Sheath |

Material / Color |

PE / Black |

|

Operating Temperature |

-40°C ~ +60°C |

|

|

Storage / Transport Temperature |

-50°C ~ +70°C |

|

|

Installation Temperature |

-10°C ~ +50°C |

|

Mechanical Characteristics

|

Fiber |

Outside Diameter (mm) |

Cable Weight (kg/km) |

Tensile Load (Min.) |

Crush Load |

Bend Radius |

|||

|

Short Term |

Long Term |

Long Term |

Static |

Dynamic |

Dynamic |

|||

|

4 |

8.7 |

82 |

1500 |

600 |

1000 |

300 |

10D |

20D |

|

6 |

8.7 |

82 |

1500 |

600 |

1000 |

300 |

10D |

20D |

|

8 |

8.7 |

85 |

1500 |

600 |

1000 |

300 |

10D |

20D |

|

12 |

8.7 |

90 |

1500 |

600 |

1000 |

300 |

10D |

20D |

|

24 |

9.8 |

131 |

1500 |

600 |

1000 |

300 |

10D |

20D |

Compliant Standard:ITU-T G651 / ITU-T G652 D, ANSI/TIA B.3, IEC-794

Outdoor Parallel Steel Wires & Steel Armored Uni-tube Fiber Optic Cable, PE

|

Number of Fibers |

9/125 |

50/125 |

62.5/125 |

50/125(OM3) |

50/125(OM4) |

|

4 |

267123004 |

267133004 |

267113004 |

267143004 |

267193004 |

|

6 |

267123006 |

267133006 |

267113006 |

267143006 |

267193006 |

|

8 |

267123008 |

267133008 |

267113008 |

267143008 |

267193008 |

|

12 |

267123012 |

267133012 |

267113012 |

267143012 |

267193012 |

|

24 |

267123024 |

267133024 |

267113024 |

267143024 |

267193024 |

Install the fiber optic cable inside of existed conduits, this need excellent tensile strength also additional steel tape armored against rodent. This kind of fiber optic cable is also available for campus cabling.

Structure & Environmental Characteristics

|

Loose Tube |

Material |

PBT |

|

Strength Member |

Material |

Steel Wire |

|

Material |

Corrugated Steel Tape |

|

|

Moisture Barrier |

Material |

Jelly Compound |

|

Sheath |

Material |

PE / Black |

|

Operating Temperature |

-40°C to +70°C |

|

|

Storage/Transport Temperature |

-40°C to +70°C |

|

|

Installation Temperature |

-40°C to +70°C |

|

Mechanical Characteristics

|

Fiber |

Outside |

Cable |

Tensile Load |

Crush Load |

Bend Radius |

|||

|

Short Term |

Long Term |

Short Term |

Long Term |

Static |

Dynamic |

|||

|

4 |

9.2 |

103 |

1500 |

600 |

1000 |

300 |

10D |

20D |

|

8 |

9.2 |

103 |

1500 |

600 |

1000 |

300 |

10D |

20D |

|

12 |

9.2 |

103 |

1500 |

600 |

1000 |

300 |

10D |

20D |

|

24 |

9.2 |

103 |

1500 |

600 |

1000 |

300 |

10D |

20D |

|

72 |

11 |

146 |

1500 |

600 |

1000 |

300 |

10D |

20D |

|

144 |

15.5 |

248 |

1500 |

600 |

1000 |

300 |

10D |

20D |

Compliant Standard:ITU-T G651 / ITU-T G652 D, ANSI/TIA B.3, IEC-794

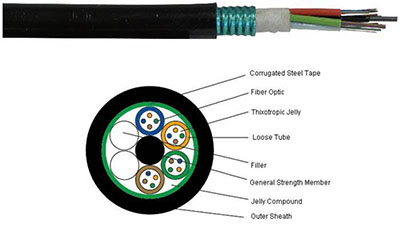

The two layer sheath provides good crush resistance performance, as well as the good mechanical and temperature performance. It performs excellent water resistance and moisture resistance especially in the direct buried application or conduit cabling.

Structure & Environmental Characteristics

|

Loose Tube |

Material |

PBT |

|

Peripheral Strength Member |

Material |

Steel Wire |

|

Diameter |

Nom. 2.0 mm |

|

|

Reinforcement |

Material |

Corrugated Steel Tape |

|

Wrapping |

Material |

Aluminium/Corrugated Steel Tape |

|

Sheath |

Material |

PE / Black |

|

Operating Temperature |

-40°C to +70°C |

|

|

Storage / Transport Temperature |

-40°C to +70°C |

|

|

Installation Temperature |

-40°C to +70°C |

|

Mechanical Characteristics

|

Fiber |

Outside |

Cable |

Tensile Load |

Crush Load |

Bend Radius |

|||

|

Short Term |

Long Term |

Long Term |

Static |

Static |

Dynamic |

|||

|

4 |

12.8 |

189 |

3000 |

1000 |

3000 |

1000 |

12.5D |

25D |

|

8 |

12.8 |

189 |

3000 |

1000 |

3000 |

1000 |

12.5D |

25D |

|

12 |

12.8 |

189 |

3000 |

1000 |

3000 |

1000 |

12.5D |

25D |

|

24 |

12.8 |

189 |

3000 |

1000 |

3000 |

1000 |

12.5D |

25D |

|

72 |

14 |

221 |

3000 |

1000 |

3000 |

1000 |

12.5D |

25D |

|

144 |

18.6 |

343 |

3000 |

1000 |

3000 |

1000 |

12.5D |

25D |

Compliant Standard:ITU-T G651 / ITU-T G652 D, ANSI/TIA B.3, IEC-794

Outdoor Steel Armored Double Sheath Multi-tube Fiber Optic Cable

|

Number of Fibers |

9/125 |

50/125 |

62.5/125 |

50/125(OM3) |

50/125(OM4) |

|

4 |

266223004 |

266233004 |

266213004 |

266243004 |

266293004 |

|

8 |

266223008 |

266233008 |

266213008 |

266243008 |

266293008 |

|

12 |

266223012 |

266233012 |

266213012 |

266243012 |

266293012 |

|

24 |

266223024 |

266233024 |

266213024 |

266243024 |

266293024 |

|

72 |

266223072 |

266233072 |

266213072 |

266243072 |

266293072 |

|

144 |

266223144 |

266233144 |

266213144 |

266243144 |

266293144 |

Premium Line fiber optic dome type splice enclosure is in hermetically sealed design, easy for assembly and re-entry. The closure is designed with a gasketed split end plate for mid-access cable application and includes an integrated stack storage basket. Max. 6 * 24 cores splice trays support up to 144 cores splice inside and no need special tools for trays fixing or unloading. This type enclosure is available for aerial or wall mount application.

FEATURES:

Fiber Optic Dome Type Splice Enclosure

|

PART NO. |

DESCRIPTION |

|

541122402 |

Premium Line FO Splice Closure, w/4 Cable Ports (2in, 2out), 48 Cores, Dome Type |

|

541132402 |

Premium Line FO Splice Closure, w/4 Cable Ports (2in, 2out), 72 Cores, Dome Type |

|

541242402 |

Premium Line FO Splice Closure, w/6 Cable Ports (3in, 3out), 96 Cores, Dome Type |

|

541262402 |

Premium Line FO Splice Closure, w/6 Cable Ports (3in, 3out), 144 Cores, Dome Type |

Premium Line fiber optic inline type splice enclosure is in hermetically sealed design, easy for assembly and re-entry. The enclosure is in compact and water-tight design, provides good impact and low temperature resistance for wide applications. Max. 8 * 24 cores splice trays support up to 192 cores splice inside and no need special tools for trays fixing or unloading. This type enclosure is available for aerial duct and direct buried.

FEATURES:

Fiber Optic Inline Type Splice Enclosure

|

PART NO. |

DESCRIPTION |

|

542222402 |

Premium Line FO Splice Closure w/6 Cable Ports (3in, 3out), 48 Cores |

|

542232402 |

Premium Line FO Splice Closure w/6 Cable Ports (3in, 3out), 72 Cores |

|

542242402 |

Premium Line FO Splice Closure w/6 Cable Ports (3in, 3out), 96 Cores |

|

542262402 |

Premium Line FO Splice Closure w/6 Cable Ports (3in, 3out), 144 Cores |

|

542282402 |

Premium Line FO Splice Closure w/6 Cable Ports (3in, 3out), 192 Cores |

Copyright © 2025 VS Tech Pte Ltd. All Rights Reserved.